Alumina ceramic structural parts

View on your phone Views: 0Category

Materials and content

Production Process

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Features

Good strength and stiffness

Good hardness and wear resistance

Good corrosion resistance

High thermal conductivity

High temperature resistance

Electrical insulation

Low dielectric constant

Product Details

Alumina Ceramic, also known as Aluminium Oxide or Al2O3, it is the one of the most widely used technical ceramic materials. It is a material with high wear resistance, high hardness, high strength, high temperature resistance and good electrical insulation, it has a very wide application in mechanial, chemical, medical, energy, electronics&electrical industries.

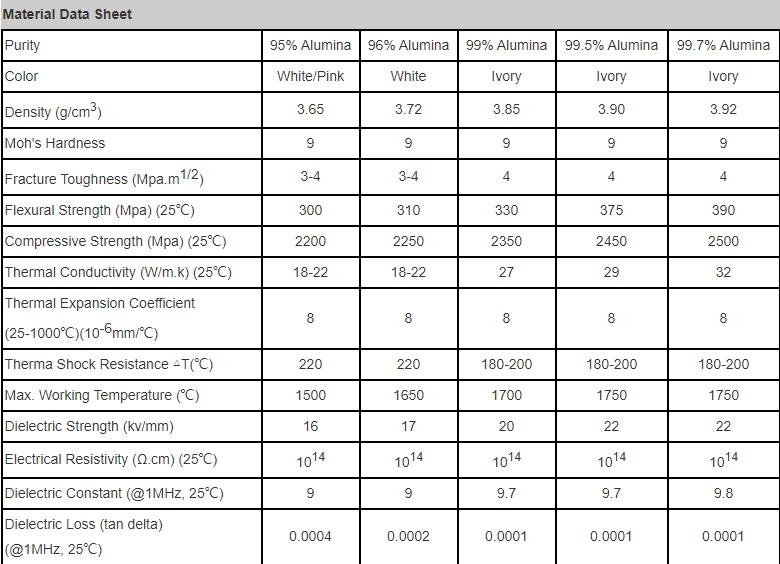

Alumina ceramic can be manufactured in a range of purities to meet different property requirement. The purity could be 95%-99.7%. Mascera provides custom production according to customers' designs or drawings, available shapes includes ceramic balls, ceramic rods, ceramic tubes, ceramic plates, ceramic discs and custome shapes.

Typical properties:

Good strength and stiffness

Good hardness and wear resistance

Good corrosion resistance

High thermal conductivity

High temperature resistance

Electrical insulation

Low dielectric constant

Application examples:

Seal Rings

Plungers or pistons for valves

Electronic substrates

High temperature thermocouple tubes

Textile eyelets or guides

Electrical insulators

Wear resistant nozzles

Ceramic parts for high temperature furnace

Forming methods for Alumina Ceramics:

Dry pressing

Isostatic pressing

Hot injection moulding

Extrusion molding

Tap casting