Zirconia ceramic blade

View on your phone Views: 0Category

Materials and content

Markets

Production Process

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Product Details

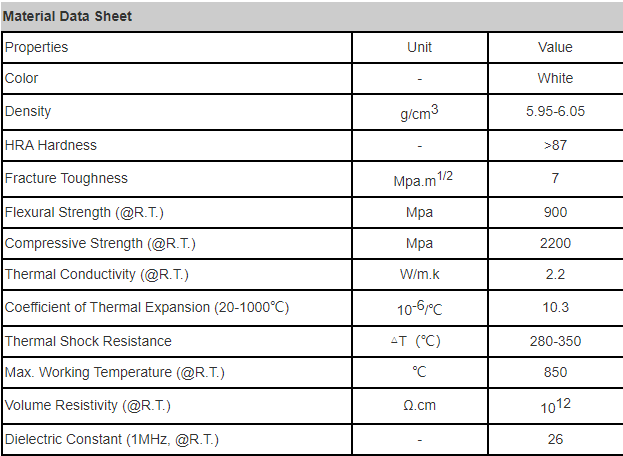

Zirconia Ceramic is usually doped with additions of some oxides (MgO, CaO,Y2O3) to make it more stable. Far now, the most widely used is Y2O3 stabilized Zirconia.Zirconia Ceramic is easier to machine than Alumina Ceramic because of the excellent fracture toughness at room temperature. The coefficient of thermal expansion is similar to steel, so it can be jointed to steel parts. Zirconia Ceramic has low thermal conductivity and superior wear resistance, it is electrical conductivity above 900℃.

Typical properties:

Excellent fracture toughness

High mechanical strength and high hardness

Very good wear resistance

High corrosion resistance

Low thermal conductivity

CTE in range of steel

Application examples:

Wire forming/drawing dies

Ceramic valve components (balls, seats, liners)

Ceramic pump liners

Mechanical seals

Ceramic cutting blades/knives

Grinding media

Thermal insulation components

Sandblasting nozzles

Medical and surgical component

Precision ceramic balls for bearings