该产品由 厦门迈仕嘉科技有限公司 发布

氧化铝结构件

手机查看产品 浏览量: 0产品类别

材料及含量

联系人信息

产品特点

强度高

硬度高,耐磨性好

耐腐蚀性能好

热导率高

耐高温

电绝缘性能好

介电常数低

产品详情

氧化铝陶瓷,也称为氧化铝或Al2O3,它是使用最广泛的工业陶瓷材料之一,具有高耐磨性,高硬度,高强度,耐高温性和良好的电绝缘性,在机械,化学,医疗,能源,电子电气工业中具有非常广泛的应用。

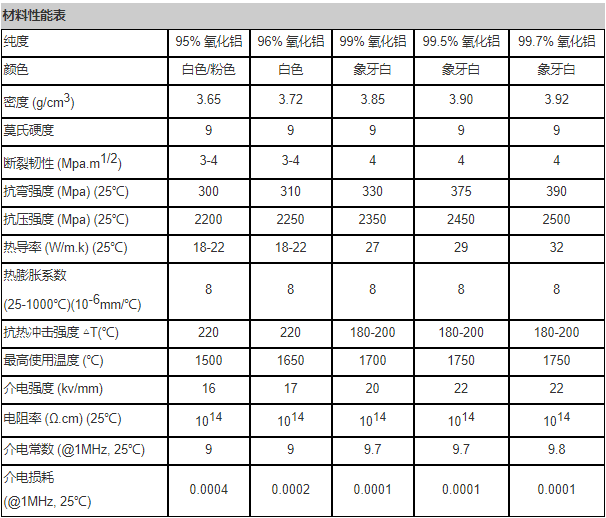

我们可以制造各种纯度的氧化铝陶瓷以满足不同的性能要求,度可以为95%-99.7%,可根据客户的设计或图纸提供定制产品,可生产的形状包括陶瓷球,陶瓷棒,陶瓷管,陶瓷板,陶瓷圆盘和定制形状。

主要性能:

强度高

硬度高,耐磨性好

耐腐蚀性能好

热导率高

耐高温

电绝缘性能好

介电常数低

应用案例:

机械密封环

阀门上的柱塞

陶瓷基片

高温热电偶保护管

纺织瓷眼、导轮

陶瓷绝缘零件

耐磨喷嘴

高温炉用的陶瓷零件

氧化铝陶瓷的成型工艺:

干压成型

等静压成型

热压铸成型

挤出成型

流延成型