Ti(C,N) Matrix Cerment Plate

View on your phone Views: 0Category

Materials and content

Markets

Production Process

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Product Details

Product name:Ti(C,N) Matrix Cerment Plate

SEM photos:

Product performance characteristics:

1. The hardness of Ti(C,N) Matrix Cerment plate is high, and the hardness of Ti(C,N) Matrix Cerment plate is higher than WC base hard alloy, generally suitable for processing cast iron, malleable cast iron, ductile iron, carbon steel, alloy steel, titanium alloy and other metal materials.

2. Ti(C,N) Matrix Cerment plates have good wear resistance and low wear rate when high speed cutting steel.

3. Ti (C, N) Matrix Cerment plate with high heat resistance, it made the tool under the high temperature of 1100-1300 ℃ can still cutting, cutting speed than the WC base of hard exceeds 2-3 times, up to 200-400 - m/min.

4. Ti(C,N) Matrix Cerment has a high oxidation resistance, and the TiO2 formed after TiC oxidation is lubricated, so the oxidation degree of Ti(C,N) foundation cermet is about 10% lower than that of WC based cemented carbide.

5. Ti (C, N) Matrix Cerment plate has good chemical stability, its made of Ti (C, N) Matrix Cerment cutting tools for cutting, cutting tool and chip work interface will form Mo2O3, nickel salt molybdate and TiO2 thin film, appeared in 700-900 ℃ is often difficult to bond, not easy to devolop tumor formation, to improve the surface quality of workpiece, the formation of mirror surface. This feature makes it very suitable for dry cutting, which helps to save production costs.

Product application:

1. The hardness of Ti(C,N) Matrix Cerment plate is high, and the hardness of Ti(C,N) Matrix Cerment plate is higher than WC base hard alloy, generally suitable for processing cast iron, malleable cast iron, ductile iron, carbon steel, alloy steel, titanium alloy and other metal materials.

2. Suitable for making high temperature resistant parts, wear resistant parts and shielding parts. Be like the guideway of machine tool, automatic teller machine prevent theft to strengthen board to wait.

3. Suitable for making corrosion resistant parts in chemical industry.

4. Suitable for making unloading plate, stamping die, punch, electronic progressive die and other stamping dies.

5. Ti(C,N) Matrix Cerment plate can be used for cutting aluminum alloy, graphite, cast iron, stainless steel, alloy steel, nickel base alloy, titanium alloy, non-ferrous metal, mainly used for face milling cutter as finishing milling, CNC machine milling blade, used in titanium alloy processing, toughness is stronger.

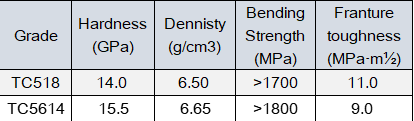

Product brand recommendation and related performance parameters:

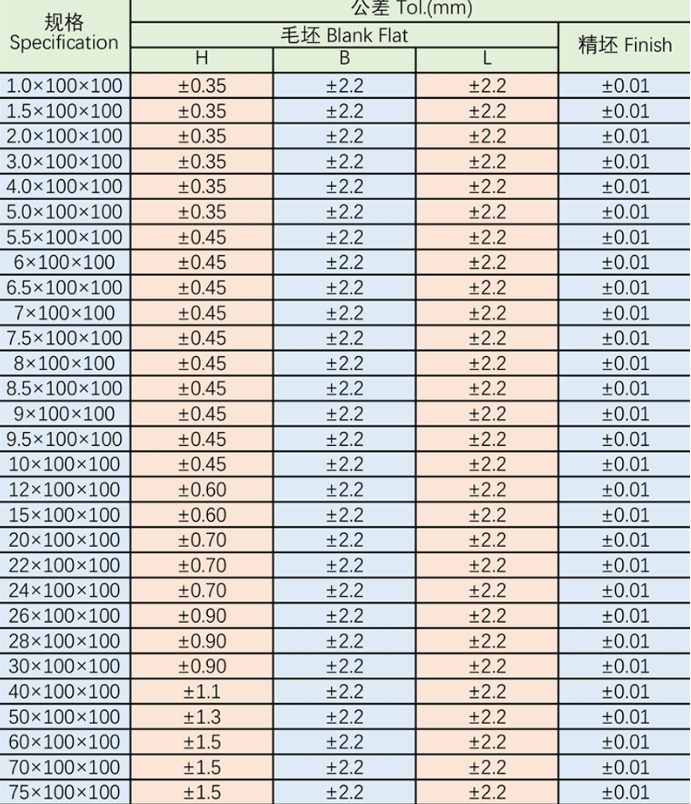

Product size:

贸易信息

| Online quote | ||||

| Price | MOQ | Lead Time | Customization | Sample |

| Negotiable | Negotiable | Contact Supplier | Yes | Yes |