Zirconium carbide powder (ZrC)

View on your phone Views: 0Category

产品特性

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Product Details

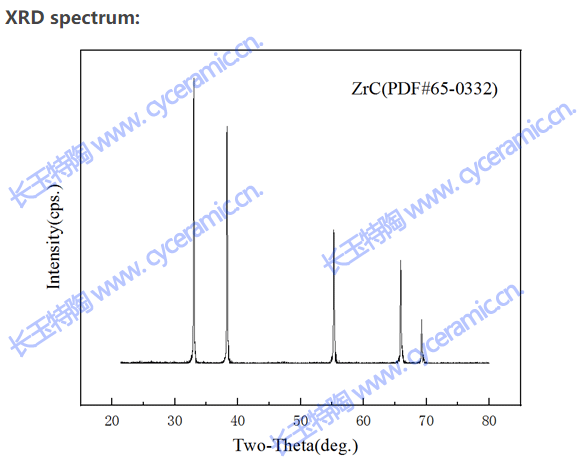

Product name: ZIRONIUM CARBONITRIDE Powder(ZrC)

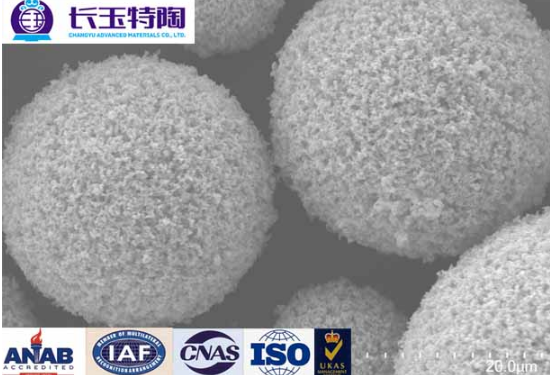

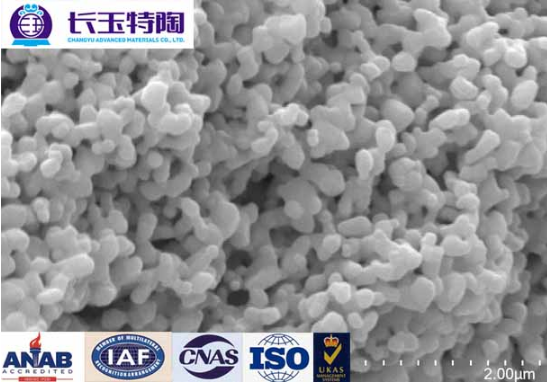

SEM photos:

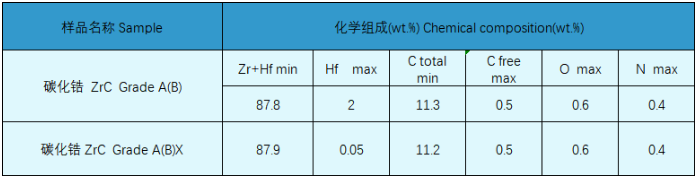

Product chemical composition

Product introductions:

Zirconium carbide melting point is 3540℃, it has high temperature resistance, oxidation resistance, high strength, high hardness, good thermal conductivity, good toughness.It is an important high temperature structural material with high melting point, high strength and corrosion resistance.

Ultra-fine zirconium carbide has excellent sintering activity and dispersibility, and is the main material and additive of various ultra-high temperature materials, hard alloys and coatings.Our company provides two kinds of specifications including hafnium and hafnium.

Product performance:

Powder Grade A(B)purity ≥98.5%

Grade A(B)X purity of powder ≥98%

Average particle size: 200-400 nm

Product usage:

1. Zirconium carbide powder can be used to prepare cemented carbide: ZrC is an important high-temperature structural material with high melting point, high strength and corrosion resistance. The strength and corrosion resistance of cemented carbide with nano ZrC were improved greatly.

2. Zirconium carbide powder can be used as a new thermal insulation textiles: it has the characteristics of highly efficient absorption of visible light, reflection of infrared. It stores energy in the material through thermal conversion when it absorbs energy at short wavelengths below 2 m, which accounts for 95% of sunlight. It can absorb 95% of the sunlight 2 m below the short wavelength, reflection more than 2 m infrared wavelength, through energy conversion, to prevent human heat loss.

3. Zirconium carbide powder can be applied to fiber: different zirconium carbide and silicon carbide powder content and the way of adding the near infrared absorption properties of the fibers, when the zirconium carbide and silicon carbide fiber content is 4% (weight), near infrared absorbing properties of the fiber best, add zirconium carbide and silicon carbide fiber shell in the near infrared absorption effect is superior to add in the core layer effect.

4. Zirconium carbide powder can be used for high temperature resistant coating: nano ZrC melting point is 3540 ℃. ZrC ceramics have good mechanical properties and high temperature resistance in harsh environment. It is one of the indispensable materials in the field of aerospace.

5. Zirconium carbide powder can be used in the nuclear industry: nano-zrc high temperature strength, high hardness, small thermal neutron absorption cross section, good radiation resistance, is used as a new material to coat the barrier layer of nuclear fuel particles.

6. Zirconium carbide powder can be used to make abrasive and abrasive tools: nano ZrC mohs hardness of 8 ~ 9, and good thermal conductivity, is a good alternative material for abrasive and abrasive tools.

Product packaging and storage:

Our company uses vacuum packing for this product.

* The above information is based on the test results of our factory and laboratory. The above information is only for reference due to the changes in the actual application conditions. We do not assume any responsibility arising therefrom.

Production Process

贸易信息

| Online quote | ||||

| Price | MOQ | Lead Time | Customization | Sample |

| Negotiable | Negotiable | Contact Supplier | Yes | Yes |