SiC Ceramic Pump - HVT serie

View on your phone Views: 0Category

Materials and content

Production Process

Product Description

- Model

- Brand

- -

- Origin

- -

- Port

- -

Contacts

Product Details

Wet parts in material silicon carbide (SiC) ceramic.

3~8 longer lifetime than metal pump!

About HVT Serie

HVT serie is desulfurization pump which has comprehensive performance; it can be widely used for transiting limestone or plaster slurry for desulfurization systems in coal power station, steel works, aluminum and petrol industry.

Why to Choose SiC Ceramic Slurry Pump?

- abrasion resistance 4 times of high chrome

- corrosion resistance to PH0~12 nearly all acid and alkali

- impact resistance to large solids

- 3~8 times longer lifetime than metal pump

- energy saving and cost reducing >20%~40%

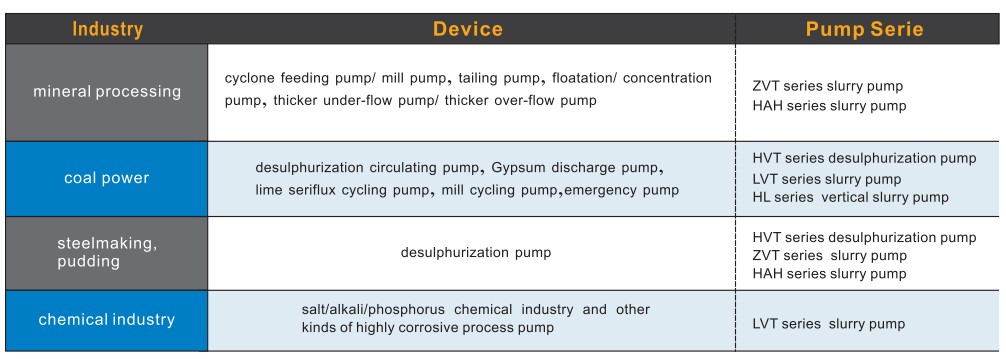

Where to use SiC Ceramic Slurry Pump?

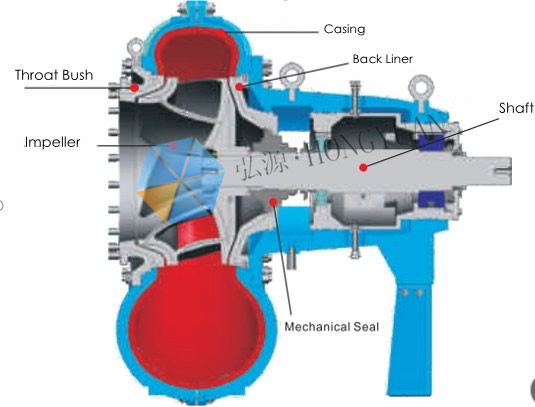

Structure of SiC pump HVT serie:

1.The wet parts are made with resin bonded SiC material, it has good abrasion and corrosion resistance. 2.The impeller can be adjusted in axial direction to keep the gap between impeller and throat bush,

so the pump can always work in high efficiency.

3.The pump is designed as a backward-pulling structure, which allows customers to disassemble impeller,

mechanical seal and shaft without taking down the suction and discharge tubes.

4.The pump shaft diameter is large but end of shaft is small, that lessens the shaft deflection in working.

5.Bearing is lubricated by thin oil. It is installed in a case with rubber seal ring for stopping water and dirt getting in.

Seal Type:

- gland seal / packing seal

- mechanical seal

Parameter Chart of HVT series: