该产品由 哈尔滨新辉特种陶瓷有限公司 发布

液相烧结碳化硅

手机查看产品 浏览量: 0产品类别

材料及含量

应用领域

生产工艺

原料材料

碳化硅(SiC)

粉体制备

-

成型工艺

-

烧结工艺

-

加工工艺

-

产品描述

- 型号

- 品牌

- 原产地

- - • 提供原产地证

- 发货地

- -

联系人信息

产品详情

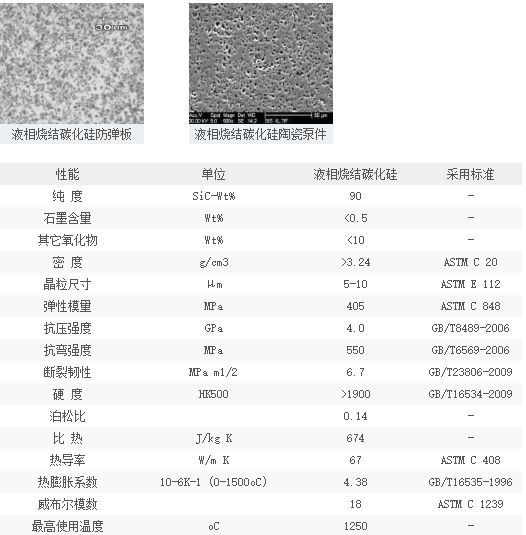

随着工业化的进展,对碳化硅陶瓷材料的要求越来越高,为提高碳化硅陶瓷的强度、韧性及使用性能,我公司开发的液相烧结碳化硅陶瓷LS-SIC,其特点是强度高、韧性好、抗冲击能力强,特别适合用于受一定冲击、交变载荷的机械零部件中使用。由于使用了提高强度和韧性的添加剂,其最高使用温度和耐腐蚀性低于无压烧结制品。我公司液相烧结碳化硅的最高使用温度为1250oC,即在1250oC温度以下强度不降低。

性能特点:硬度较高(>2100);强度高(>650MPa),比重小(3.24g/cm3),生产成本低于无压烧结碳化硅制品,适用于大批量生产。

适用于:对耐磨性能要求一般,但抗弯强度和抗冲击性能较高的工件,如用于清水工况的大尺寸机械密封用密封环,轻质防弹装甲用的硬质面板, 形状、受力较复杂的轻质耐磨件等。