Alumina Ceramic Roller

View on your phone Views: 0Category

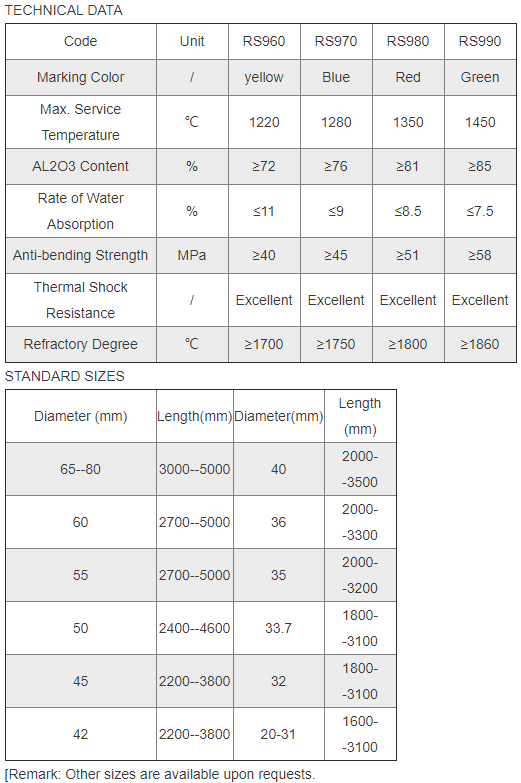

Materials and content

Markets

Production Process

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Product Details

HOW TO USE CERAMIC ROLLERS PROPERLY

①The ceramic refractory fiber (30-50mm) should be insert in to the roller with length about 60-80mm, but do not exceed 100mm.

②Roller protective coating will effectively reduce the erosion of chemical and reduce the roller break. Therefore, before inserting into the kiln, coating should be laid on surface of the rollers. The length of the coating should be 100mm longer than that of the effective width of the kiln, and the thickness should be 0.8mm-1.2mm.

③Before inserting into the kiln, the rollers should be fully dried against the kiln or on top of the kiln(1-2 days is available)

④Periodically and duly clear the dung on the surface of roller. The roller is some kind of fragile material, when clearing, please do not beating, impacting as well as any other ways which easily cause mech.

⑤it is better under 800 ℃ to changing the rollers. Inserting or taking out of the rollers as quick as possible. The rollers taken out need correct cooling method to avoid emergency cooling of the part and cause damage.

⑥ When take out of the rollers from high temperature, the rollers should be quickly rotated, the best way is put the roller in the moving stand with refractory fiber, keep it moving when the temperature is under 600℃, or warp the rollers with ceramic fiber to make it cool down .The roller can not directly contact with the ground, and avoid to contact with the cold metal or other cool objects.

⑦The rollers exchanged should be clear up. The straightness and diameter should be inspected for continuous.