3 Piece Threaded Ceramic Ball Valves

View on your phone Views: 0Category

Materials and content

Production Process

Product Description

- Model

- Brand

- -

- Origin

- - • Offer certificat of origin

- Port

- -

Contacts

Product Details

Specification:

Type: 3 Piece Threaded Ceramic Ball Valves

Size: DN15-DN80(1/2”-3”)

Pressure Rating:

PN10,PN16,PN25,PN40,CL150,CL300,JIS10K, JIS 20K, 1000WOG

Body Material:

ASTM A351 CF8, CF8M. CF3, CF3M, Incoloy 825, Hastelloy C276

Trim Material:

ZrO2, 99% Al2O3,99.7%Al2O3,SSIC, STC, Si3N4

End Connection:

NPT Threaded, BSP Threaded, G Threaded, R Threaded, Socket Welding, Butt Welding

Typical Applications:

3 piece ceramic ball valves are widely used for many slightly corrosive and abrasive applications, some typical applications are listed as following: Waste Water,Oil,Corrosive and erosive gas,Ash,Medium contain solid particles,Acid,Alkali,Mud Slurry,Some other corrosive and/or abrasive mediums.

Design Features:

Design and Manufacture: ASME B16.34

Face-to-Face Dimension: Manufacturer Standard

End: NPT Threaded, BSP Threaded, G Threaded, R Threaded, Socket Welding, Butt Welding are all available on request

Pressure-Temperature Rating: ASME B16.34

Inspection and Testing: API 598

Body Material: ASTM A351 CF8, CF8M. CF3, CF3M, Incoloy 825, Hastelloy C276

Working Temperature: -46℃ to180 ℃

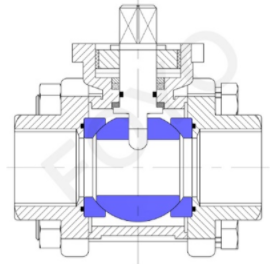

3 piece ceramic ball valves have same structure like general soft seated and metal seated 3 piece ball valve, except material of ball and seats are replaced by advanced ceramics. Because of the good properties of advanced ceramics, 3 piece ceramic ball valves can replace most common soft seated and metal seated ball valves in corrosive and abrasive applications

1. 3PC body design: 3-PC body With middle body and two adapters, as following detailed drawing illustrated. The valve body has an integral ISO 5211 mounting pad ,so lever, pneumatic actuators and electric actuators can be assembled onto valve directly and easily. Well ground ceramic ball and seats ensure operating torque of 3 piece ceramic ball valves is much lower than general ball valves, smaller actuators can drive it and cost is saved.

Ceramic-to-Ceramic spherical seated: The perfect spherical seal between fine ceramic ball and seats ensure that 3 piece ceramic ball valves have a Class VI shutoff. The anti-scratch design between ball and seat, which prevent the deep sealing surface from being marred and scratched by particles.

贸易信息

| Online quote | ||||

| Price | MOQ | Lead Time | Customization | Sample |

| Negotiable | Negotiable | Contact Supplier | Yes | Yes |