AUTO and Motor Catalyst Support

View on your phone Views: 0Category

Materials and content

Production Process

Product Description

- Model

- Brand

- -

- Origin

- -

- Port

- -

Contacts

Product Details

CO,HC,and NOx go through purifier made of multi-hole cordierite catalyst honeycomb carrier, it make the gases more active and do oxide-reducing chemical reaction. CO is oxidized into no color and no poison CO2 under high temperature. HC chemical compound is oxidized into H2O and CO2. NOx is restored into nitrogen gas. The poisonous gases are made into unpoisonous gas to make them pure.

Physical Properties:

1) Compressive strength

2) Porosity/water absorption

3) Bulk density

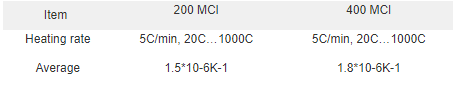

4) Coefficient of Thermal Expansion

5) Thermal Conductivity

1.5…1.6 W/mk at temperature 25C…600C

6) Specific Heat Capacity

At:100C/200C/300C

800KJ/Kg950KJ/Kg2000KJ/Kg

7) Continuous High Temperature Durability

Maximum shrinkage of length after 100 hours at 1200C

200MCI 400MCI

Maximum:0.5% 0.1%

8) High Temperature Stability

Maximum shrinkage after 100 hours at 1450C

200 MCI400 MCI

Maximum2.0%2.5%

9) Gas Flow Resistance

Flow speed 16m/s200 MCI400 MCI

Pressure drop {10-2mmAg/mm} 60130

10) Structural Integrity to Thermal Shock

(Cooling with water)

Cracks start at approx. 800C

No destruction of ceramic bodies until approx. 1180C

11) Softening temperature

Definition: temperature, at which the instantaneous rate of thermal expansion is zero.

Procedure: analogous to coefficient of thermal expansion; determination with extrapolation.

Minimum: 1380C

贸易信息

| Online quote | ||||

| Price | MOQ | Lead Time | Customization | Sample |

| Negotiable | Negotiable | Contact Supplier | Yes | Yes |